Everything You Wanted to Know About Maple Syrup

A History of Maple Syrup

With the help of graphic designer Scott Gladd, the Cosman & Webb logo was created. European settlers traditionally collected syrup in wooden buckets hung from a yoke placed across their shoulders, like the one shown in the image.

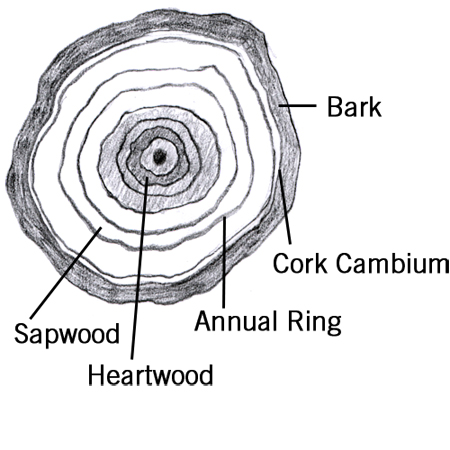

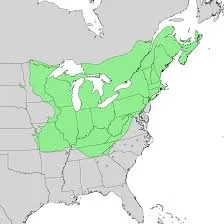

Before the arrival of European settlers in 1608, the custom of collecting and boiling the sap of sugar maples had long been practiced by the Indigenous peoples of eastern North America. Each spring, Indigenous communities moved from their winter hunting grounds into the sugar bush. There, they made v-shaped incisions in the bark of sugar maples with stone tools, fixed hand-carved, concave pieces of bark or reeds to the incisions, and leaned woven birch baskets against the trees to collect the flowing sap.

Indigenous peoples originally used sap as cooking liquid for stews and for curing meats, but over time they began processing the sap into syrup. In the beginning, they would heat stones in a fire and then drop them into sap-filled vats made of moose hide or bark to evaporate the water content – a very slow and painstaking process. Later, they boiled sap in brass kettles placed over a fire.

Maple syrup became a valuable trading commodity when a method for transforming syrup into sugar was discovered through straining, reheating, thickening, and stirring. The granulated sugar would be packed into birch bark cones, tied together and hung from ceilings for storage. Maple syrup was also transformed into maple candy by pouring it into wooden molds or directly into the snow and leaving it to harden.

Canada's early European settlers learned the skills of tapping trees and making syrup from these Indigenous communities. Over time, methods evolved: instead of making v-shaped cuts in the bark, settlers manually drilled holes into trees and pushed wooden spouts into them. They hung buckets from nails below the spouts to protect the sap from strong winds or animals and used iron pots over open fires to concentrate the sap.